From the April 1998 issue of Car and Driver.

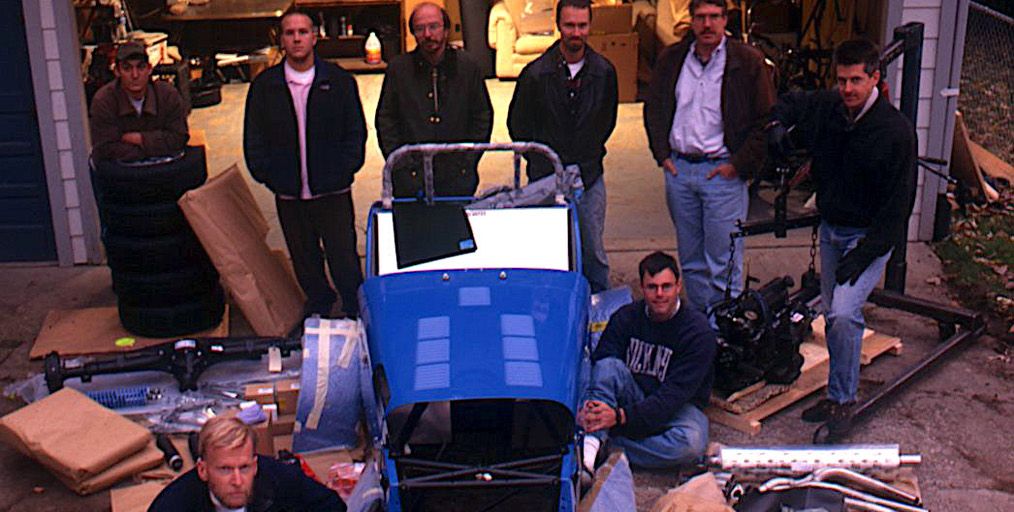

The last time we built a kit car was one summer weekend in 1979. Okay, the pronoun should be they, since none of us was on the masthead back then except Pat Bedard, who at that time still had enough brain cells to vanish on the weekend in question, and Larry Griffin, who didn’t. The car was a Kelmark GTS, a VW-powered two-seater that looked vaguely like a Ferrari Dino and cost $13,678. It took 10 persons (two doing the work, eight handing them wrenches) two days to put that sled together (see image below). That Car and Driver staff had one distinct advantage we didn’t: The president of the company that made the Kelmark was in attendance. And the project involved a considerable amount of beer.

After researching all the available kits, we chose the one that seemed most unlikely to wind up half-finished, buried under a tarp. (For the intellectually challenged, that means we picked the easiest one to build.) It’s a Caterham kit. It cost a bit more than the ’79 project—$27,664, to be exact.

In 1973, Caterham bought, from Lotus, the rights to a British sports car called the Lotus 7. Caterham has been updating and improving the car ever since. Still, building a kit car can be frustrating, as you’ll see. In the Caterham’s case, it was really easy to get tied up in mental knots over the infuriating mixture of English and metric fasteners. But that’s to be expected with any kit car.

The photographs document our remarkable progress. (Okay, at least they prove we built the thing.)

Uh, Read the Manual, Butthead

The Caterham’s instruction manual reminds me a little of a prescription drug whose bottle fails to reveal what dose to swallow. I mean, it’s better than, say, acute phlebitis, but some surprises accrue. I installed the rubber fuel filler upside down, for instance. This entertained my co-workers, but had I been alone at the time, I am fairly sure a claw hammer would have sailed through some plate glass.

Speaking of which, I also installed the windshield. I studied the manual for 30 minutes, muttering over and over, “This can’t be right—only three tiny bolts per side?” Then—as a last resort, merely to teach someone a valuable lesson—I installed the thing exactly as the text advised. It fit perfectly. The moral? The Caterham is a frolic for garage-aholics, but journey nightly to that edifice prepared to grapple with a dozen childproof caps. —John Phillips

The Mysterious Shift Linkage

There are two shifter levers in the Caterham—one you can see, and one you can’t. At first glance, it looks like the shift lever will be so far from the driver that he’ll never be able to reach it. Your first impulse is to phone the company and complain that it’s sent the wrong transmission. What you find is that two flat, four-inch bars bolt to the thing that looks like the shift lever and extend back to meet the lever you actually use to shift, the one with a knob. This one is only slightly easier to reach but is still difficult to work. The bolts holding the flat bars ride in plastic bushings. They’re a bit long for the job, and they’re all-threads. Not exactly Mercedes’ level of engineering, but it works. —Phil Berg

You Guys Ever Hear of Labels?

After installing the rear suspension, I want to go to the Caterham works and knock heads. Throwing hundreds of fasteners into a few large unlabeled bags creates exactly the sort of aggravation that turns people off from ever getting involved in these kits. Worse, some very critical fasteners were missing! (Imagine sorting through the fasteners for an hour only to discover a major suspension bolt and the axle breather cap missing.) Listen up, you factory wonks: Group the fussy little bits in smaller labeled bags, based on where they’re supposed to go, ferchrisakes! And another thing: I was perplexed by how rarely the instructions called for lubrication of parts. Given my personal distaste for rust (try working on an old car), I slopped lube over everything I put a wrench on. I now have a warm feeling inside knowing that all the parts working their way loose for the owner will, nonetheless, be corrosion-free. —Don Schroeder

Problems? It’s Always the Ignition

Thirty years ago, before microchips usurped command of automotive engines, self-respecting car nuts were thoroughly familiar with changing spark plugs, ignition points, condensers, distributor caps, and distributor rotors, as well as adjusting a carburetor’s idle speed and mixture. When the engine ran worse (or not at all) after these ministrations, there was one rule to remember: The problem is always the ignition system. We had almost forgotten this rule when we tried to fire up our Caterham for the first time. There was not a hint of combustion, even after the mechanical fuel pump had filled the carburetor float bowls and filled the garage with fumes. We first checked the distributor orientation by ensuring that the rotor was pointing toward the No. 1 spark-plug wire when that cylinder’s intake and exhaust valves were closed. It wasn’t, and after making the necessary adjustments, the engine fired but ran roughly. We then wasted about half an hour adjusting the four mixture screws in the dual side-draft Webers. What we should have done was recheck the firing order. The manual called for 1-4-3-2. We were wired for 1-4-2-3. We switched the two center cylinders’ plug leads and dried their gasoline-soaked spark plugs, and the Caterflarn fired immediately and settled into a smooth idle. As I said, it’s always the ignition. —Csaba Csere

Being a Contortionist Helps, Too

The only thing trickier than fitting a pair of legs and feet into the footwell of a Caterham is fitting one’s head and shoulders down there. This must be done to see where the ignition key goes (it’s underneath the dash), to connect the wiring, and to engineer the hand brake. I say engineer because the manual provides only the vaguest hint as to how the hand-brake parts were meant to fit together.

The close confines down there serve to intensify the effects of carpet adhesive on one’s state of euphoria, too. You could use that as an excuse when the carpet ends up all wrinkly, but actually, it wrinkles because, as supplied, it doesn’t fit the kinked shape of the center tunnel and shifter housing. The seats, of course, don’t move, and as in a Viper, the Caterham’s pedals are supposed to be adjustable. But after studying the instructions, we decided that the reengineering required to adjust the pedals would make the hand-brake installation look like screwing in a light bulb. It’s easier to scrunch into the driver’s seat. —Frank Markus

The Sounds and the Fury

Amazing. It was 8:30 a.m., and all the engineers—Webster, Markus, Schroeder, Idzikowski, and the head pettifogger, Csere—were in Webster’s garage, working! I figured they must have spent the night. Schroeder was studying a schematic of the car’s axle, although I noticed the instruction book was upside down. Csere announced that the 3/16ths was his favorite wrench. (What kind of guy has a favorite wrench?)

Idzikowski was, as usual, trying to force something into something that wouldn’t accept it, and swearing. Some fool had put all the nuts and bolts into a big bowl, and Webster was staring stupified into it, mouth agape, like the Secret of Life was hidden in there. (It is, Larry.) At 9:20, Phillips realized angrily that no one had brought beer. In response, he spent four hours drilling six tiny holes in the sheetmetal for the fuel filler, then collapsed. Smith arrived, tuned the junkyard radio to Golden Oldies, and went off for a nap. Phil Berg explained the Theory of Washers, in Norwegian, to an audience riveted, as you can imagine, to his every word. By noon, Markus still had all nine fingers! Our photographer, the very strange Aaron Kiley, performed a series of dog-flatulence impressions without using his hands. Sneering, Idzikowski forced the engine in. Csere said, “I’ll be right back.” Three-to-one he went prowling the aisles of Ace Hardware, searching for some naughty 3/16ths, and he was never seen again. I went out and bought 18 Italian hoagies, with oregano, olive oil, and vinegar. Webster howled. “Hey, where’s the mayo?” That was it—I’d seen enough. —Steve Spence

The First Drive Gives Rise to the Joy of Parenthood

With sore backs and chewed-up hands, and after 60 worker-hours toiling away in a cold garage overcoming numerous hiccups, the magic moment finally arrived. Well, truth be known, the Caterham was far from being completed, but hey, we needed a bit of excitement to prevent a mutiny of volunteers. So without any lights, fenders, or hood—on a brisk 30-degree day—we took a few laps around the block.

With wheel alignment done the old-fashioned way—by eye—we fired the engine and crept out of the garage. Elation! The car actually moved under its own power. Even better, the just-bled brakes brought the car to a halt. Hey, we built this thing, and so far, it worked!

Gingerly, we pulled out onto the street and gently accelerated, keeping all senses on full alert for any unnatural noises or behavior. Again, we braked to a full stop. Feeling a bit more confident we then accelerated again and upshifted into second. The engine let out a blat-blat-blat. We steered. The car turned! Is this how Henry felt with Ford No. 1?

Even with the eyeballed alignment the Caterham went down the road straight, accelerated smoothly, and stopped when we applied the brakes. Better yet we got a small taste of the trademark Caterham driving experience. You know, lots of power, not much weight, wind in the hair (and teeth and torso and crotch), horrendously cramped cockpit. This injected another round of enthusiasm as we went back to work.

After another 40 worker-hours, we sent the completed car to our local shop for a proper alignment—purely as a safety precaution.

Real validation of our assembly would come only after a thorough thrashing, so we headed to the track. The 1380-pound Caterham makes the most of its 135 horsepower. Without fanfare, it scampered to 60 mph in only 5.1 seconds. That’s in the same league as a Corvette. Top speed was 105 mph, and—trust us—don’t go near that speed with the soft top in place. Although the assembly manual advises against it we pushed it to its top speed and were immediately rewarded with a terrifyingly loud whoomp! followed by some horrendous flapping of the top. The plastic windows had blown out. Doh!

Then a problem with the brakes developed—the rears locked early, sending stopping distances, from 70 mph, to 190 feet. For such a light car, we expected better, but we were sure a little bit of brake tuning would fix the problem.

Success, however, returned at the skidpad, where the car cruised around the circle at an astounding 0.94 g. The last Porsche Boxster we tested only managed 0.86 g.

Overall, we couldn’t be more pleased with the Caterham’s performance. Surprisingly, it doesn’t exhibit the sort of rattletrap feel you’d expect from a build-it-yourself kit car. Then again, describing the Caterham as a modern car is a stretch. Crash protection, for example, verges on the nonexistent.

Although this was our baby, it came with nuisances. Only those with ballerina feet will ever be able to operate the pedals properly. Getting in with the top on is an exercise in body contortion, and it’s awfully tough not to feel vulnerable in a car that barely reaches over the wheel tops of most other vehicles.

In the U.S., Caterham kits range from a $22,030 solid-axle, 84-horsepower Classic GT to a $32,900 de Dion–equipped Sprint. If you are not the brave, adventurous type—you know, like us—you could pay your Caterham dealer $2500 to assemble the car for you. But that means you’d miss the inner thrill of turning the steering wheel that you assembled, the glee of hearing the exhaust pulsing through pipes you carefully sealed, and the satisfaction of waxing fenders you installed. If you’re after the ultimate car-bonding experience, this is it.

Specifications

Specifications

1997 Caterham Classic SE

Vehicle Type: front-engine, rear-wheel-drive, 2-passenger, 2-door convertible

PRICE

Base/As Tested: $23,245/$27,664

ENGINE

pushrod 8-valve inline-4, iron block and head

Displacement: 103 in3, 1691 cm3

Power: 135 hp @ 6000 rpm

Torque: 122 lb-ft @ 4500 rpm

TRANSMISSION

5-speed manual

DIMENSIONS

Wheelbase: 88.5 in

Length: 133.0 in

Curb Weight: 1380 lb

C/D TEST RESULTS

60 mph: 5.1 sec

1/4-Mile: 14.1 sec @ 95 mph

100 mph: 16.3 sec

Rolling Start, 5–60 mph: 5.4 sec

Top Speed (drag ltd): 105 mph

Braking, 70–0 mph: 190 ft

Roadholding, 300-ft Skidpad: 0.94 g

#Build #Kit #Car

Source link